Compound Masterbatch in Saudi Arabia

HardLine Industries’ Compound Masterbatch range is designed for high-performance applications requiring mechanical strength, dimensional accuracy, and superior processing flow. Our compounds are engineered for PE, PP, PS, ABS, HIPS, and specialized polymers used in technical molding and industrial manufacturing.

Key Performance Attributes

- Excellent melt flow for complex molding

- Improved rigidity, toughness & impact strength

- Dimensional stability under stress

- Thermal & chemical resistance

- Tailored formulations for specific applications

Polymer Compatibility

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

- High Impact Polystyrene (HIPS)

- Engineering polymer blends

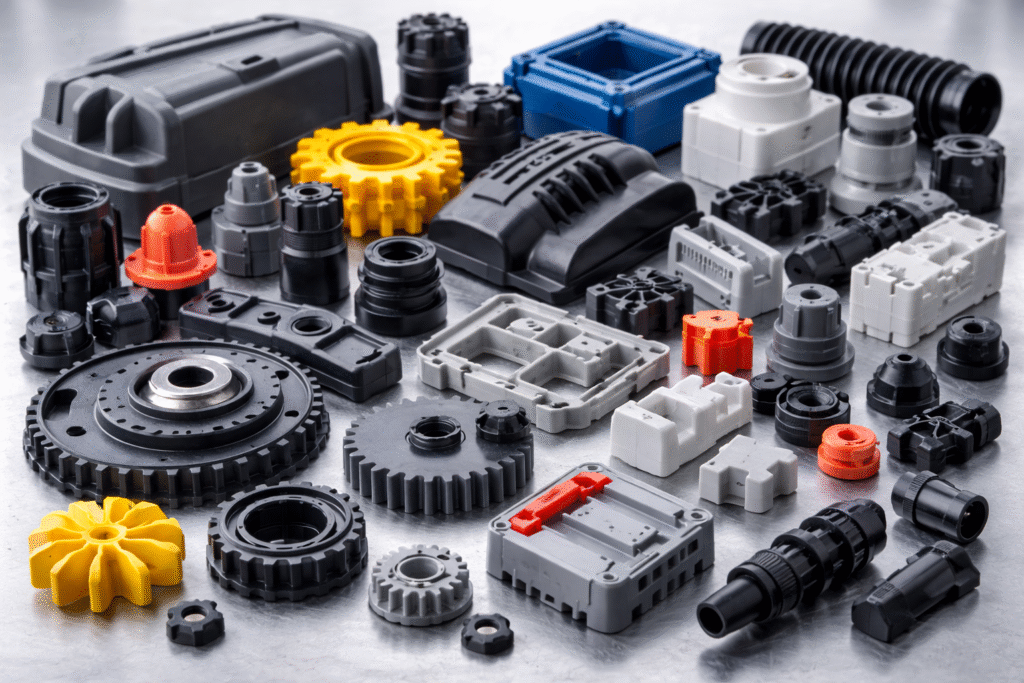

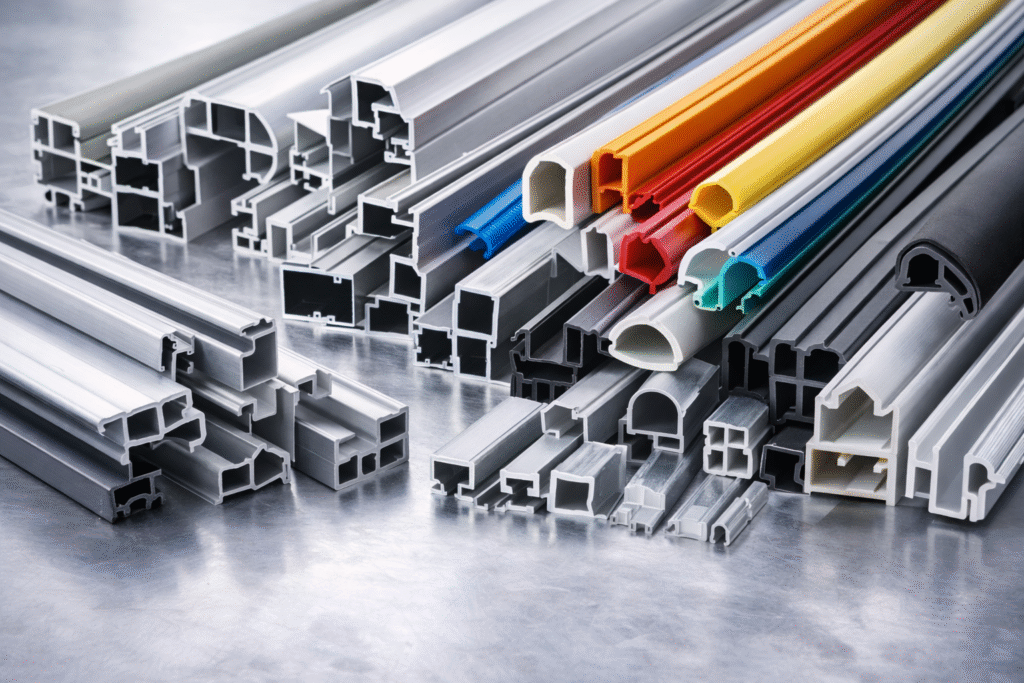

Applications

Industrial molded parts

Automotive components

Consumer products

Extrusion profiles

FAQ's

What is compound masterbatch used for?

Compound masterbatch is used to enhance mechanical properties, processing flow, durability, and dimensional stability in plastic components produced by injection molding and extrusion.

Which industries use compound masterbatch in Saudi Arabia?

Industries include furniture, electrical appliances, automotive components, packaging, industrial machinery, and consumer goods.

What polymers are compatible with compound masterbatch?

Our compounds are compatible with PE, PP, ABS, PS, HIPS, and various engineering polymers.

Does compound masterbatch improve mechanical performance?

Yes. It enhances tensile strength, rigidity, impact resistance, and heat stability, depending on the application.

Can you create custom compound formulations?

Yes. We formulate custom compounds based on application, color, strength requirements, environmental exposure, and processing conditions.